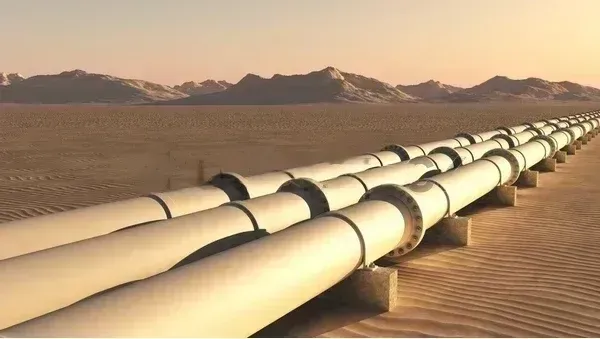

Laying oil pipelines

Oil pipeline construction projects can be divided into distinct stages with different costs. Pre-engineering, conceptual engineering, detailed engineering, fabrication, construction, operation, and abandonment are all included in these phases. While every aspect of the cost is considered, this is done in sections. The costs associated with all activities, including conceptual engineering, fabrication, and installation, are regarded as distinct, dealt with at various stages of the pipeline life cycle, and not considered integrated.

As interdependent entities, these costs must be evaluated. Therefore, when considering the financial aspects of pipelines, one should take a look at the total cost related to the general life cycle. This is particularly in the beginning phases of a reasonable plan. When life cycle cost (LCC) is factored into the pipeline design process, it makes it possible to create economically optimized pipelines.

The life cycle cost model of decision has the advantage of being extremely adaptable. Any aspect of the system being designed can be analyzed. This analysis applies to pipeline engineering at all design and management levels. It can be used as a management tool to decide which training programs to put in place to improve workforce efficiency. Alternatively, an engineer could use it to determine the most cost-effective strategy for avoiding corrosion failure (for example, high-quality materials, and a corrosion allowance).