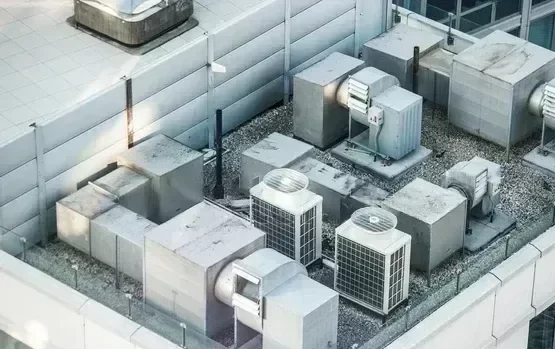

HVAC

It is difficult to cool a large building, even though the fundamental principles of refrigeration remain unchanged. The number of opportunities for waste increases with building size. For instance, there may be hundreds of feet of ductwork in a large building, and clogs can form anywhere in that subsystem. That, in turn, makes it more difficult for the system to work, restricts airflow, and lowers HVAC results. As a result, the HVAC system as a whole requires more maintenance when there is more space. Proper planning and installation of the system are also important. In addition to meeting current requirements, it must be used to achieve long-term efficiency maximization.

Your cooling system’s heart is a compressor, possibly a Trane CHHB100, which compresses the refrigerant to raise its temperature and pressure. The refrigerant is pushed through the system and to its next stop as a result of this. To liquefy the vapor, the condenser blows hot outside air over it. The expansion valve decreases the vapor’s pressure. The evaporator then transfers heat, transforming the cool liquid into a much warmer gas.

To keep the system running, it needs to be checked and tested weekly, monthly, quarterly, and annually. Various segments of the framework can easily be separated into a very complex central air framework. This is so you don’t have to suspend air conditioning work for the whole term of your support. Plan to conduct checks on weekends, after hours, or during times of low traffic if your system lacks redundancy. It is difficult to cool a large building, even though the fundamental principles of refrigeration remain unchanged.

The number of opportunities for waste increases with building size. For instance, there may be hundreds of feet of ductwork in a large building, and clogs can form anywhere in that subsystem. That, in turn, makes it more difficult for the system to work, restricts airflow, and lowers HVAC results. As a result, the HVAC system as a whole requires more maintenance when there is more space. Proper planning and installation of the system are also crucial. In addition to meeting current requirements, it must be used to achieve long-term efficiency maximization.

However, as long as you know all about the blower, condenser, evaporator, and warm extension valve, you can continuously pinpoint issues in your system during disposal. Despite the fact that the compressor receives a lot of attention due to the amount of work it does, the majority of issues are not caused by the compressor; rather, they are caused by failures in maintenance or issues with the environment elsewhere.

In order to keep the system running, it needs to be checked and tested on a weekly, monthly, quarterly, and annual basis. Various segments of the framework can easily be separated into a very complex central air framework. This is so you don’t have to suspend air conditioning maintenance for the whole term of your contract. Plan to conduct checks on weekends, after hours, or during times of low traffic if your system lacks redundancy.